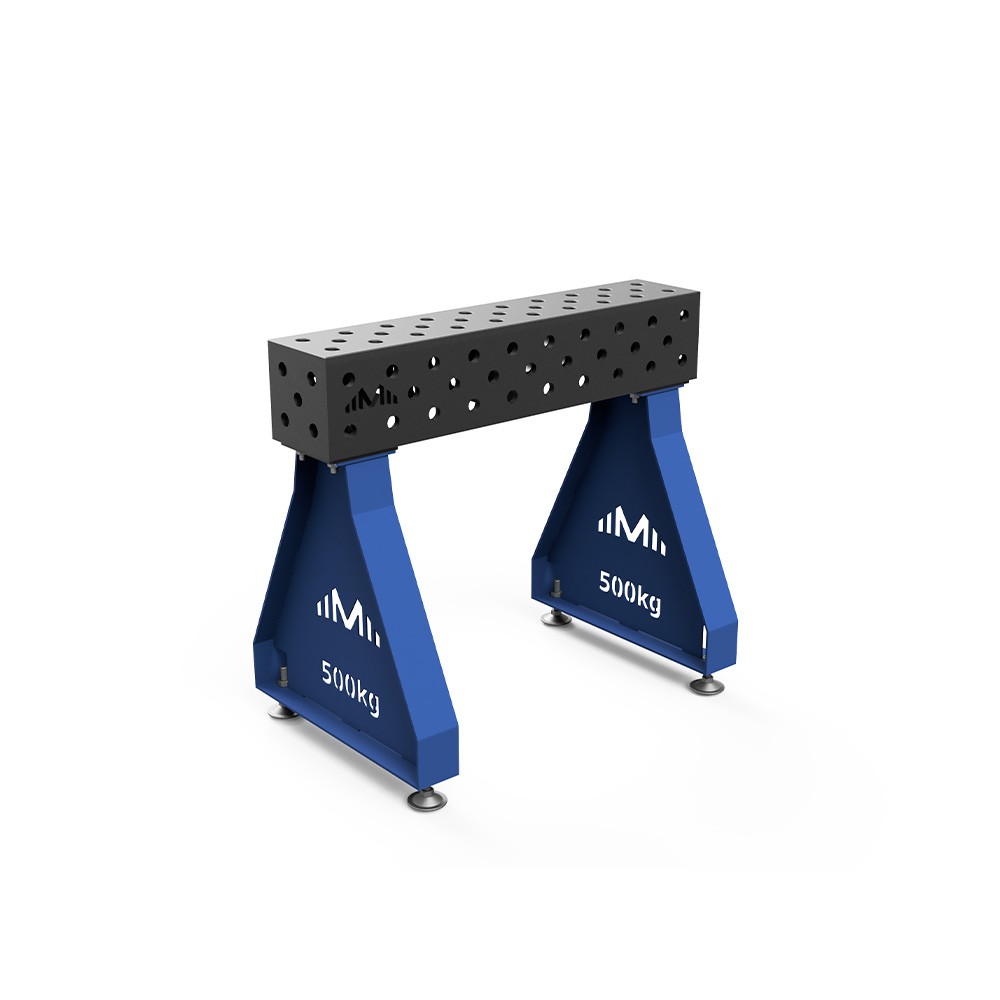

Welding Support 1000 mm – Mobile Base with a 12 mm Plate

The 1000 mm version with a 12 mm plate was designed for quick retooling and work in limited space. Its lighter construction makes it easier to reposition by a single operator while still providing sufficient rigidity for stable guidance of profiles, frames, and assemblies extending beyond the main table. Instead of improvised blocks, you get a consistent reference point—a flat surface and constant height—making it easier to maintain geometry during tack welding and continuous welds.

Where 1000 mm / 12 mm Works Best

This configuration is ideal for service bays, assembly lines, and work cells where parts rotate between stations. The shorter format doesn’t block torch access, fits between clamps and stops, and the lighter mass shortens setup time. If you often change clamping layouts, the lightweight 12 mm plate simply speeds up work—you move the support where needed while maintaining repeatable height.

Fast Setup and Axial Operation

Begin by aligning the support with the table height, then place the workpiece and arrange clamps so forces act toward the base, not pushing the part across the plate. Over 1000 mm, the support carries the profile’s end weight and keeps a constant distance to the working plane, reducing deformations during heating. The shorter base makes small adjustments by a few millimeters easier without dismantling the whole setup.

Geometry Control Without Excess Weight

The 12 mm plate doesn’t “over-armour” the station but delivers enough rigidity for most workshop tasks. For slender and thin-walled elements, even support minimizes warping and twisting, ensuring straighter welds. If workpieces vary in stiffness along their length (e.g., local reinforcements), add another support to distribute the load and keep alignment.

Integration with Hole Grid and Accessories

The support is available in variants compatible with popular system table grids. This means you can use standard pins, clamps, and stops without adapters. In a typical setup, the support maintains height (Z-axis), while the main table provides XY positioning with stops and clamps—speeding up repetition in series production.

Example Applications

Most often, the 1000 mm support is used as a “shelf” for profiles extending beyond the table, in assembling smaller frames and panels, and when preparing sections for integration into larger modules. In tight workshop areas, the shorter base lets you get closer to the weld seam and control the pool more easily without clashing with other accessories.

Daily Work Benefits

Better ergonomics and less improvisation save real time. A stable reference level reduces corrections after cooling, and the operator quickly returns to repeatable setups.

- Faster retooling thanks to lighter construction,

- Stable support beyond the table edge over 1000 mm,

- Easy fine adjustments without dismantling the setup.

Practical Tips

First lock the height adjustment mechanism, then distribute clamps along the weld path so forces press toward the base. For longer parts, add a second support (another stand or height stop) to spread loads evenly and avoid misalignment. After work, clean the plate from spatter and chips; a thin anti-spatter layer in the arc zone makes maintenance easier and preserves a smooth contact surface.

FAQ – Frequently Asked Questions

What is the 1000 mm, 12 mm welding support used for?

For stable support of workpieces extending beyond the table and maintaining constant height during tack welding, joining, and continuous seams.

When to choose the 12 mm version instead of 15 mm?

When mobility and fast retooling in tight areas matter; its lighter weight makes it easier for single-operator handling.

Does it work with system tables?

Yes, it comes in versions compatible with popular hole grids, so you can use standard pins, clamps, and stops.

How to minimize deformations with long profiles?

Align the support with the table, distribute clamps along the weld line, and if needed, add a second support to balance the load.

Can one person handle repositioning?

Usually yes. The shorter format and 12 mm plate make it suitable for single-person handling and frequent setup changes.