Connector for supports – set of 2 pcs – system 16/28

Technical specifications:

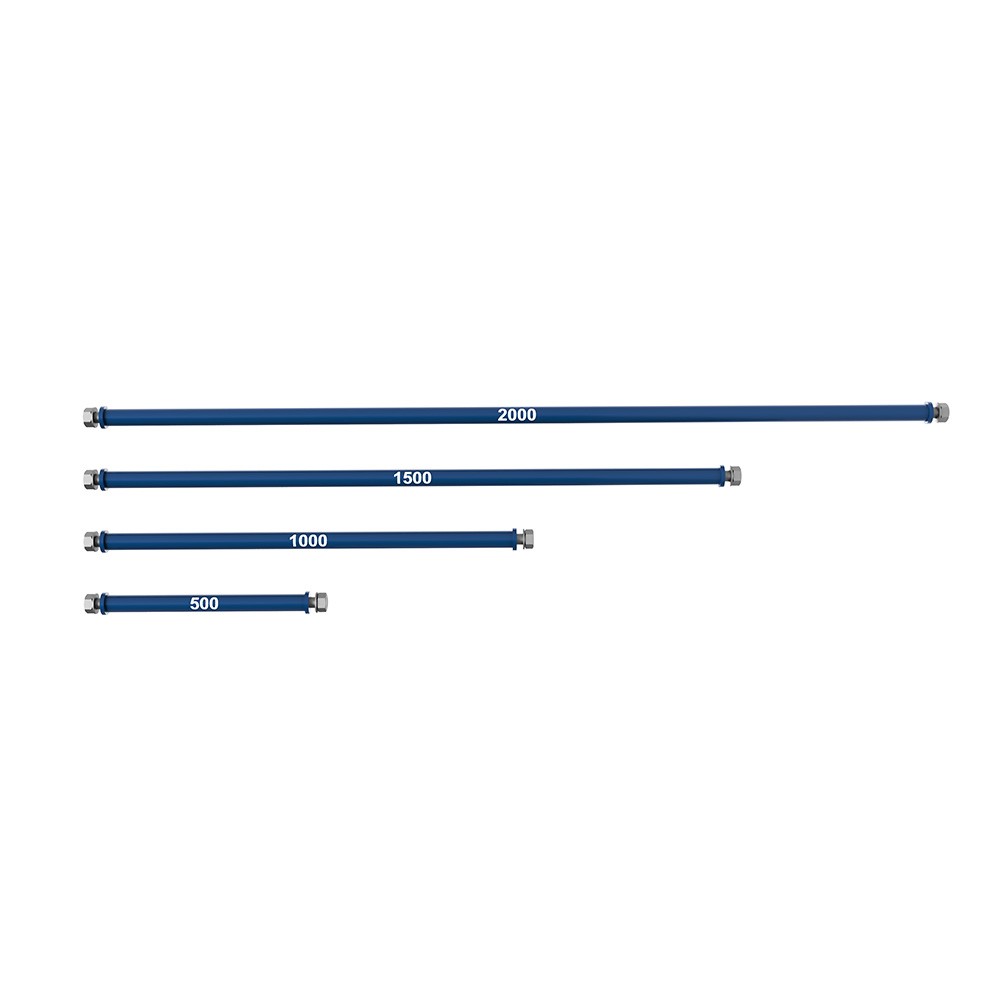

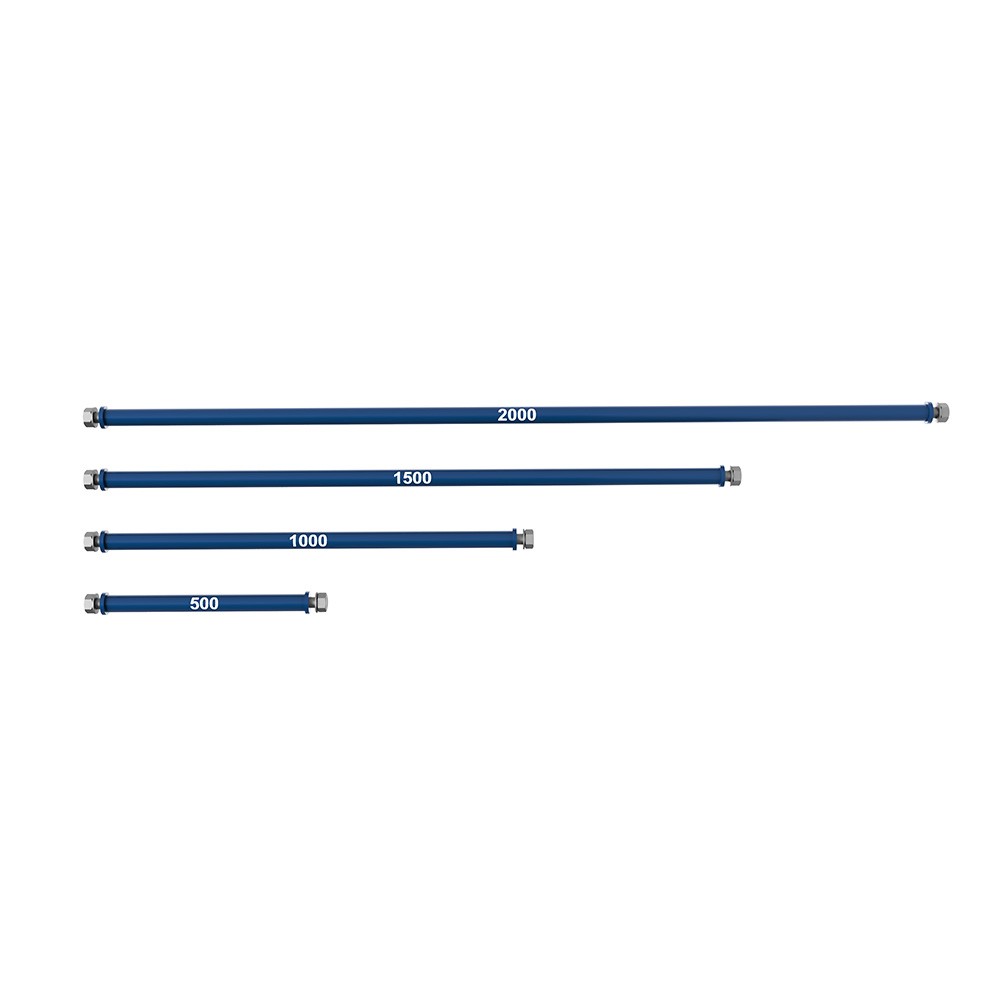

- Length: 500, 1000, 1500, 2000 mm (optional)

- Diameter: 42 mm

- Hole system: 16 or 28 (optional)

- Set includes: 2 pcs of connector

Welding table and support connectors are essential workshop accessories that allow stable joining of two worktables or a table with a welding support. Their main task is to maintain a constant distance between the work surfaces, ensuring rigidity, dimensional accuracy, and safe support even when working with heavy steel structures.

Using connectors allows you to configure the workstation precisely for each task. The connector, mounted between two tables or between a table and a TRESTLE support, keeps them at the correct spacing and prevents unwanted movement during welding, tacking, marking, or assembly work. This solution is especially useful when working with larger components and you need one continuous working surface instead of several separate tables placed loosely side by side.

The key role of a connector is to enforce a fixed position between two (or more) work modules. This directly affects welding precision. When tables are aligned and reinforced with a connector, the structure placed on top remains steady and doesn’t shift under clamping or alignment pressure. In practice, this means shorter setup times, fewer corrections, and higher dimensional repeatability in series production. Such geometric control is crucial for workshops producing frames, brackets, fixtures, steel components, or furniture parts.

Connectors are available in four standard lengths: 500 mm, 1000 mm, 1500 mm, and 2000 mm. Each option serves a different purpose depending on workstation size and workpiece dimensions.

The 500 mm connector is ideal for compact work areas. It enables joining two tables or a table and a support at a short distance, perfect for precision assembly, prototyping, and small-series production. It’s appreciated by workshops that frequently change setups and need flexibility without occupying too much space.

The 1000 mm version is the most universal choice. It provides comfortable working space for medium-sized structures and ensures stable, easy access to all parts of the work surface. This is the most popular option in production and service workshops where stability and flexibility are equally important.

The 1500 mm connector is designed for larger configurations and long workpieces. It enables building extended work areas by spacing tables apart while maintaining full rigidity and alignment. Ideal for supporting long profiles, frames, or large steel assemblies.

The 2000 mm version is used for industrial workstations handling large-scale structures, long profiles, or assemblies requiring extended support. This length allows multiple table modules and supports to act as one continuous, stable work platform.

Connectors are available in two variants matching the most common hole standards: Ø16 mm and Ø28 mm. This allows perfect adaptation to the tables and supports used in your workshop. The Ø16 mm system is typically used with light and medium-duty tables where precision and ergonomics are key, while the Ø28 mm system suits heavy-duty industrial tables designed for high load-bearing applications. Choosing the correct connector ensures a secure, play-free fit and reliable load transfer between connected elements.

Each connector is made of high-strength structural steel, precisely machined to maintain dimensional consistency and smooth contact surfaces. This precision guarantees a rigid connection: tables and supports joined by the connector stay perfectly aligned even under heavy clamping or welding pressure. The result is a stable base that can be modularly extended instead of investing in a single oversized table. This solution is particularly advantageous in dynamic workshops where workstation layout changes daily depending on project requirements.

The 1000 mm connector is the most universal option. It provides stability and convenient access to the entire surface, making it the top choice for most welding workshops.

Yes. The connector can be used both between two tables and between a table and a TRESTLE support, allowing you to build a stable, modular workstation.

The Ø16 system is used in light and medium-duty tables, while Ø28 is intended for heavy industrial tables. They differ in hole diameter, so the connector must match your table’s system for proper fit.

No. Installation requires only standard workshop tools. The connection is quick and secure, with no additional adjustments needed.

Yes. The connectors can be quickly removed to reconfigure the workstation layout. This makes them ideal for workshops that frequently change setups depending on project size and type.