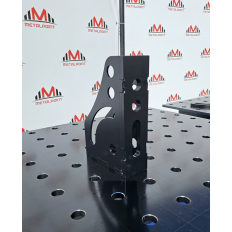

Welding Support 1500 mm – Agile Assistance with a 12 mm Plate

This support was designed for working with longer elements where stable guidance and quick station adjustments are crucial. The 1500 mm format provides reliable support along a significant section, while the 12 mm work plate reduces the unit’s weight—making it easier to reposition alone and adapt to current tasks, without compromising the stiffness needed in welding and assembly.

When the 12 mm Variant Has the Advantage

It performs best where clamping setups change frequently: short and medium production runs, diverse dimensions, or limited workspace around the table. The lighter plate makes maneuvering between stations easier, and thanks to its stable construction the workpiece doesn’t “drift” during tack welding or continuous seams. It’s a smart compromise between mobility and rigidity—especially when a single operator manages the entire station.

Setup and Work Ergonomics

First, align the support with the table height, then place the workpiece and set clamps so that forces act in the direction of guiding rather than pushing the material off-axis. In practice, the support functions as a table extension—taking on the load and maintaining a constant level, eliminating stresses from makeshift props. The weld line stays more predictable, and corner geometry requires fewer corrections after cooling.

Integration with Table Systems and Accessories

The support is available in variants adapted to popular hole grids. This allows you to use standard pins, clamps, and stops, maintaining process consistency across the entire workshop. Station setup becomes intuitive: height reference on the support, XY positioning on the main table, and quick repeatability of the same settings in subsequent cycles.

Geometry Control with Longer Profiles

When working with thin-walled profiles, pipes, or beams, even support across 1500 mm reduces warping and twisting under heat. If the workpiece has varying stiffness along its length (e.g., local reinforcements), distribute clamps so forces don’t cause misalignment. If needed, add an extra support or stop to spread the load and keep the axis steady.

Everyday Benefits

Adding the 1500 mm (12 mm plate) support to your process organizes the workstation and reduces preparation time. The operator spends less effort “chasing” the level and more on weld quality. This translates into repeatability and fewer corrections after cooling.

- Faster adjustments thanks to lighter construction,

- Consistent 1500 mm support without improvised props,

- More stable geometry of the workpiece under heat.

Practical Tips

Place the support in line with the table and lock the adjustment mechanism before clamping the workpiece. For long elements, distribute clamps along the weld path so forces press toward the base rather than sliding the material. Regularly clean the plate of spatter and chips, and apply a light anti-spatter layer in the weld zone to maintain a smooth, repeatable contact surface.

FAQ – Frequently Asked Questions

What is the 1500 mm, 12 mm welding support used for?

For stable support of longer workpieces and maintaining a constant level during tack welding, joining, and continuous seams—it functions as a table extension.

How does the 12 mm variant differ from the 15 mm?

It is lighter and easier to reposition, speeding up workstation setup while maintaining the stiffness needed for typical workshop tasks.

Does it work with system tables?

Yes, it is available in versions matched to popular hole grids, so you can use standard pins, clamps, and stops.

How to minimize deformations in long profiles?

Align the support with the table, distribute clamps along the weld line, and if necessary add a second support to spread the load evenly.

Can one person handle repositioning the support?

Usually yes—the reduced weight of the 12 mm variant supports single-operator handling, especially when configurations change frequently.