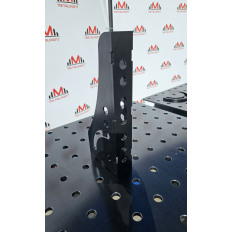

Welding Support 1500 mm – Stable Table Extension for Long Workpieces

The 1500 mm support with a 15 mm work plate is designed for handling profiles, frames, and structural sections that require even support beyond the standard table length. The thicker plate provides high rigidity and resistance to deformation, while the compact 1500 mm format makes it easy to maneuver in tighter workshop spaces. In practice, the support acts as a rigid, reliable extension of the table: it carries the weight of the workpiece, maintains height along the axis, and prevents sagging during heating.

When 1500 mm Works Best

This size is the right choice when you need longer support than short stands offer, but prefer not to switch to very long, heavier solutions. 1500 mm is the sweet spot for door frames, closed profiles, longer panels, or medium-weight beams. The support makes tack welding and assembly easier without makeshift spacers; the workpiece stays level, and the weld path remains predictable from start to finish.

Height Adjustment and Axial Work

The adjustable mechanism allows quick leveling with the table height, even on uneven floors. Once set, it locks securely, creating a repeatable reference point that doesn’t flex under load. For longer profiles, consistent support across 1500 mm reduces twisting and warping from heat, helping maintain parallel edges and stable angles in structural joints.

Compatibility with Accessories and Hole Grid

The support is available in variants adapted to popular system table hole grids, allowing the use of standard pins, clamps, and stops without adapters. This is crucial when multiple stations operate in the same hall—accessories remain consistent across processes, and the operator saves time. In daily practice, the support acts as a permanent height base, while clamps and stops on the main table define the XY position of the workpiece.

Platform for Profiles, Pipes, and Sections with Variable Stiffness

When working with thin-walled profiles or long pipes, stable support prevents arcs and local deflections in the weld zone. The 1500 mm level stabilizes the material, resulting in straighter welds and less post-weld straightening. If the element has varying weight along its length (e.g., welded reinforcements), distribute clamping points so the main forces press the material along the axis instead of pushing it off track.

Workstation Organization and Repeatability

Instead of using makeshift props from scrap profiles, you get a uniform, rigid platform designed for maintaining level. This simplifies repetitive assemblies and shortens setup time. Returning to the same reference is easy: just replicate the height and hole grid position—no need to “search” for settings again.

Benefits You’ll Notice from Day One

Adding the 1500 mm (15 mm) support improves workflow predictability and reduces corrections after cooling. Less improvisation at the setup stage means better quality control and shorter production cycles.

- Stable, long support – consistent level across 1500 mm,

- Fast adjustment and repeatable settings in series,

- Fewer deformations and less post-weld straightening.

Practical Tips

First align the support level with the main table, then set stops and clamps. For very long profiles, add a second support or auxiliary stops to distribute weight and prevent misalignment. In areas exposed to spatter, apply a thin anti-spatter layer—this makes cleaning easier and keeps the contact surface smooth. After work, store the support in a dry place and regularly clean chips from the plate and adjustment areas to maintain precision for years.

FAQ – Frequently Asked Questions

What is the 1500 mm, 15 mm welding support used for?

It provides stable support and guidance for long workpieces; it acts as a rigid extension of the table, maintaining height in axis and carrying the load.

When to choose 1500 mm instead of 2000 mm?

When you need long but more manageable support in limited space, or for medium-length and medium-weight workpieces.

Does it work with system tables?

Yes, it is available in versions adapted to popular hole grids, so you can use standard pins, clamps, and stops.

How to minimize deformations during welding?

Distribute clamps along the weld line, keep the support level, and add a second support for longer profiles to spread loads evenly.

Is the 15 mm version too heavy for frequent repositioning?

The thicker plate increases rigidity but can still be repositioned by one person; for frequent changes, it’s best to record positions in the hole grid for quick repeats.