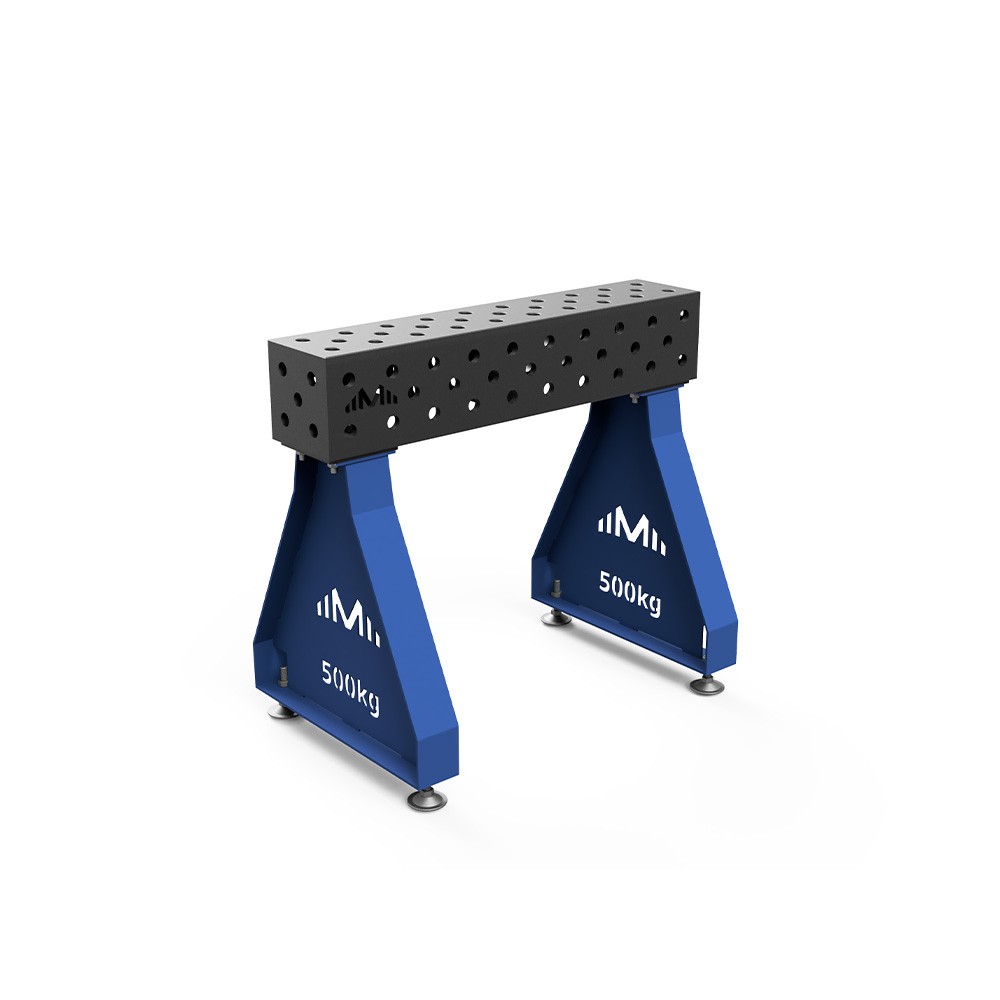

Welding Support 1000 mm – Compact and Rigid Base for Workpieces

The 1000 mm support with a 15 mm plate is a nimble table extension that combines compact size with high rigidity. It is ideal where space is limited but reliable support is needed for profiles, frames, or components extending beyond the main table. The rigid 15 mm plate eliminates “springing” and helps maintain geometry during tack welding, joining, and continuous welds.

Where the 1000 mm Version Excels

Choose the 1000 mm format when workstation mobility and work in tight areas are key: along assembly lines, in service bays, or wherever elements frequently rotate between stations. The shorter base easily fits between clamps and stops, and with full height and rigidity it provides secure support for profiles partially extending beyond the main table. It is also perfect for tasks where the workpiece must stay aligned but doesn’t need full-length support of 1500–2000 mm.

Alignment and Axial Guidance

Start by matching the support height with the table. Once the adjustment mechanism is locked, place the workpiece and position clamps so forces press toward the guiding direction rather than pushing the material across the surface. In practice, the support functions like a rigid shelf—taking the load beyond the table edge and maintaining a stable distance from the working plane. Thanks to its shorter length, fine adjustments by a few millimeters are easier without moving the entire setup.

Everyday Benefits of the 15 mm Plate

The thicker plate increases resistance to local deflections and improves edge control, reducing corrections after cooling. For slender or thin-walled elements, it minimizes arcs and twisting from heat. The short, rigid base also works well as a transfer point: you can safely align the workpiece, set the distance, and move on to final clamping without the risk of sagging ends.

Compatibility with Hole Grid and Accessories

The support is available in versions compatible with popular system table hole grids, allowing seamless use of standard pins, clamps, and stops. This equipment consistency shortens retooling time—operators can repeat the same hole positions without adjustments. In typical setups, the support ensures constant height, while the main table defines XY positioning with stops and clamps.

Example Applications

The 1000 mm support is most often used for assembling smaller frames and panels, handling profile sections extending beyond the table, and preparing parts for integration into larger assemblies. Its compact format makes it easy to maneuver between stations and position close to the welding zone without blocking torch access.

Results in Daily Use

Daily work benefits from simple habits: level base, repeatable positions, and less improvisation. A short, rigid support ensures these three factors happen naturally.

- Faster adjustments in tight work areas,

- Stable support beyond the table edge,

- Fewer geometry corrections after cooling.

Practical Tips

First set the height and lock the adjustment mechanism, then place clamps along the weld path. For longer workpieces, consider adding a second support or height stop to distribute the load evenly and avoid misalignment. Regularly clean the plate of spatter and chips; a thin anti-spatter layer in the arc zone will speed up maintenance and preserve a smooth contact surface.

FAQ – Frequently Asked Questions

What is the 1000 mm, 15 mm welding support best for?

For stable support of workpieces extending beyond the table, especially in tight spaces and during frequent adjustments.

How does 1000 mm differ from 1500/2000 mm?

It is more compact and mobile—easier to place near the welding zone and simpler to adjust without moving the entire setup.

Does it work with system tables?

Yes, it is available in versions compatible with popular hole grids, allowing the use of standard pins, clamps, and stops.

How to minimize deformations during welding?

Match the support height with the table, distribute clamps along the weld line, and for longer profiles add a second support.

Can one person set it up?

Usually yes. Its shorter format supports single-operator handling; once positions are recorded in the hole grid, they can be repeated in seconds.